UTI and the Future of Career Training

UTI and the Future of Career Training

A conversation with the CEO of Universal Technical Institute - Jerome Grant

Even schools with a very long history of success have found themselves upended by the circumstances of this year.

For more than half a century, UTI has been a leader in helping students prepare for automotive, diesel, welding, CNC (computer numerical controlled) machining, and other skilled trades fields—all at our 12 campuses in eight states. It hasn’t been easy, but we have made incredible progress toward a brighter future for all our students and graduates.

This Blog is Based Off of Our Podcast Episode - Listen Here:

Responding to a Global Crisis

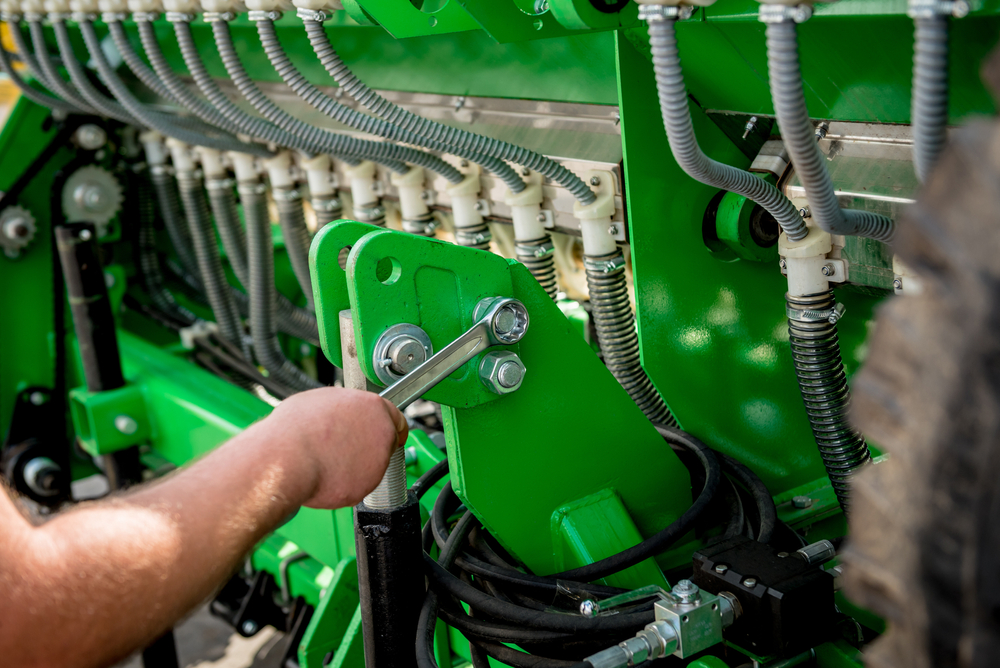

Our focus is, as always, on our students, our faculty members, their well-being, their safety, and continuing to offer them safe, quality education to support their career goals. Now, before the pandemic hit, our education was solely delivered face-to-face, hands-on on our campuses. About half of our curriculum happens in a classroom, with an instructor either demonstrating or talking about some skills that are necessary. And about half happens in the lab—hands-on with all the equipment and tools that you would expect to use on the job. This year, we redesigned our courses to take the whole classroom experience online and to provide our students with a higher level of support. Our team worked tirelessly to make this happen.

First of all, our 600 instructors stepped up in March and were real heroes. We engaged almost every one of them to help us develop the online content. You’ve got master technicians who’ve been out in the industry for decades, and for many years their teaching methodologies have been solidly hands-on, face-to-face, and in the labs. This was a significant transition for them. I’d be lying if I said that some of them didn’t reach out to me and said, “Wow, this is so different. I don’t know if I can do it.” But we gave them a lot of support from our education group and through our digital partners, and they pivoted very quickly to become digitally savvy. We’re very proud of what they’ve done, and now they’re saying things like, “Hey, let me rerecord that session because now that it’s digital, I can bring these interactive elements into it.” We believe this kind of innovation will only continue to improve as we go forward. I couldn’t be prouder of our faculty and staff and the way they rose to the occasion to support our students.

The online portion of the course is taught much in the same way it’s taught in a classroom: We have video-based instruction, discussion sections, virtual forums, regular office hours. Our labs, meanwhile, are operating just as they were before—with a really important distinction, which is class density. Our class sizes have evolved to meet the guidelines of the CDC (Centers for Disease Control), which have shifted throughout the year as their understanding of the virus has changed. Today, our classes are designed to promote physical distancing, the wearing of masks and gloves, and the sanitization of the space. And with the ability to spread out our lab spaces, it’s given us the opportunity to keep operating all of our student services virtually, including financial aid, career counseling, and course enrollment. Students can even take a virtual tour of every single one of our campuses.

Shifting toward the Future

Everyone is looking for the new normal, but I actually think this is it. This pandemic has altered the way we interact with people on a daily basis. While there may be a day when we return to completely face-to-face instruction, we’ve found that we can be just as effective in reaching students wherever they are through online instruction for at least half of their program. We actually graduated over 1,300 new techs this summer, since reopening in May, getting students out into great jobs in transportation, collision, CNC, welding, and more.

In fact, I think online learning actually offers something that a strictly hands-on curriculum doesn’t, which is flexibility. Right now, in this environment—with millions of unemployed Americans—giving up a current job to prepare for a new career isn’t an option for very many people. But with many of our campuses offering labs in morning, afternoon, and evening sessions, in addition to putting half our curriculum online, we can provide even more flexibility for our students. Plus, students can complete the online portion of their training asynchronously—whenever it works for their schedule. That’s just not something we could have accomplished with a completely hands-on curriculum: You were either an all-morning student, an all-afternoon student, or an all-evening student, and you were in our building twice the amount of time. In this new environment, we can reach out to students who previously could not make the time commitment by offering this blended curriculum.

But I don’t think these changes are specific to the career college industry either; we’re seeing it across the education spectrum. My 8-year-old daughter is in the next room in a virtual third-grade classroom right now and will likely stay that way for the rest of the year. The outcomes that teachers are producing in students are actually quite remarkable, and I think that as we move to distance learning and virtual learning, we’re finding new ways to interact with students in ways where we can really help them progress. Students will still need to do the hands-on work if they want to be an auto mechanic or a diesel mechanic or a welder or a CNC machinist or a motorcycle technician or a marine technician, so they’ll still have to prove their proficiencies and practice their skills. But in this blended learning model, we’ve found an optimal way for students to begin learning the concepts, seeing the demonstrations, and interacting with each other and with faculty before they even get into the labs to get their hands dirty.

Lessons in Leadership

We’ve stayed in close communication with our 11,000 students, and one of the things we found out early during the crisis is the fact that about 26 percent of our students either had no technology to engage online or they only had handheld technology, such as smartphones. We didn’t believe that a smartphone was the robust experience we were going for in terms of our online curriculum; it wouldn’t be conducive to working in forums, chats, and complex discussions. Through the timely and generous help of the Department of Education and the Higher Education Relief Fund, we were able to provide computers with all of the relevant learning materials for each of our students. I think it was exactly what those funds were meant for in the first place, to do tangible things that directly support students and keep them moving forward in successful educational experiences.

While there are some students that have shied away from digital learning—preferring to be in a classroom with an instructor, this type of learning is not something that’s natural to them—we’ve managed to create opportunities to connect with instructors and peers in a virtual environment. That’s where our Zoom forums, office hours, discussion sections, and virtual events come in, to give our students more of that human interaction experience. And when they’re on campus, students are getting a more personal experience in smaller lab groups. In spite of all the distancing requirements, we’re building a sense of community.

It is a challenging environment. Many of the students that are coming to us right now may have lost a job in another area of the economy and are looking for something that’s durable and something that they can move forward with. We work very hard when students engage with us as enrolled students to see if we can’t get them jobs in industry while they’re moving through our curriculum. So we take it very seriously that when students engage with us, our employment specialists can get them up and running in part- or full-time industry jobs while they’re going to school with us. Our early employment program brings in a number of our major employers who have set up ways to employ students from the moment they start at UTI. And then, when they graduate, they can move on to their professional careers at UTI as well. We also have proud partnerships with leaders in the field and industry brands who help our students learn—and who are eager to employ skilled technicians like UTI graduates. We’re committed to helping students pursue their ASE (Automotive Service Excellence) certification and brand-specific certifications so they’re prepared to work for familiar names like Porsche, BMW, Peterbilt, Harley-Davidson, and Mercury Marine.

It all starts with getting the training you need to prepare for a new hands-on career! To learn more about Universal Technical Institute and to apply for the program of your choice, visit www.uti.edu.

More From Universal Technical Institute

Motorcycle Mechanic Careers with Motorcycle Mechanics Institute

The Future of Motorcycle Mechanic Careers with Motorcycle Mechanics Institute Meet Motorcycle Mechanics Institute As one of the leading providers of professional training for skilled motorcycle technicians, Motorcycle Mechanics Institute (MMI) offers one of the largest motorcycle training group of schools in the nation. Motorcycle…

Leave a Reply Cancel reply

- - ADVERTISEMENT - -

Categories

- Alumni Series (13)

- Automotive (57)

- Aviation (15)

- Business (14)

- Business & Arts (18)

- Career College Expositions (7)

- Career Development (96)

- CCC Blog (1)

- CCC Podcast (9)

- College Resource (90)

- College Showcase – Lincoln Tech (6)

- College Showcase – New Jersey (8)

- College Showcase – Pennco Tech (1)

- College Showcase – Universal Technical Institute (2)

- Continuing Education (154)

- Cosmetology (3)

- Counselor Resources (108)

- Criminal Justice (3)

- Dental Assistant (2)

- Education (109)

- Financial Literacy (17)

- Health Sciences (50)

- Heritage Series (3)

- High School Recruitment Series (4)

- Housing Series (10)

- HVAC (8)

- Imagine America Scholarships (12)

- Information Technology (17)

- Massage Therapy (5)

- Mechanical Sciences (109)

- Medical Assistant (12)

- Millennial Student Series (4)

- News (11)

- Nursing (22)

- Online education (13)

- Pandemic Proof Series (4)

- Personal Finance (17)

- Podcast (90)

- Research (11)

- Road Map Series (2)

- Scholarships (12)

- Social Media Series (4)

- Strata Tech (3)

- Student Success (29)

- Study Tips (3)

- Time Managment (1)

- Top 10 (10)

- Trucking (2)

- Uncategorized (14)

- Universal Technical Institute (19)

- Veteran Affairs (8)

- Welding (24)

- Women in Skilled Trades (3)

Tags

- - ADVERTISEMENT - -