Choosing a Career Path in 2020: Mechanical Sciences

Choosing a Career Path in 2020: Mechanical Sciences

Maybe school has never really been your thing. Maybe the idea of sitting behind the same computer, in the same desk chair, day after day is agonizing. Maybe the idea of doing the same thing for the rest of your life as a way to earn a living is even more agonizing. But a job doesn’t have to be that way. And when you’re on the right career path, neither does school.

If the traditional American ideal of white-collar “success” just doesn’t appeal to you, don’t worry. There are other options, where your skills will be in demand, you’ll be able to focus your work ethic on something tangible, and you’ll be able to solve real, physical problems day after day.

Sure, sometimes it feels like the world runs on computers. And that’s becoming more and more true, but it doesn’t tell the whole story. Even as processes and transactions become more automated, it’s still necessary to move goods from place to place, to harness power that turns into energy, and to keep our physical dwellings safe and comfortable. So really, as it has for decades, the world runs on mechanics. From cars to planes to pipes to air conditioners, the people with the specialized skills to create, install, maintain and repair these mechanical systems will always be in demand.

The U.S. Department of Labor expects employment of installation, maintenance, and repair occupations to grow by about four percent between 2018 and 2028, which will result in about 233,200 new jobs in that time.

While it’s impossible to know how new technologies will impact the opportunities available in the field (think about a career like solar photovoltaic installation, which is currently the fastest-growing occupation 2018-2028, by a lot. It wasn’t even ranked a few years ago!), new opportunities will continue cropping up every year.

Plus, even more established career opportunities, like becoming an electrician, aren’t going anywhere. Their faster than average growth is even more impressive when you consider how many people currently hold jobs as electricians. Just 10% expected growth means a projected 74,100 new job openings by 2028.

There are a lot of job opportunities in the field of mechanical sciences that don’t technically require more than a high school education, but you should consider looking into a training program regardless. The return on investment is often worth it. Usually, colleges and universities with mechanical degree and certificate programs also have strong relationships with area employers and can help you find a job more quickly. Applicants who don’t have formal training, on the other hand, will probably be overlooked by those who do. The Bureau of Labor Statistics agrees. “Of these workers,” says the BLS, “those who have completed formal postsecondary training programs or achieved ASE certification should enjoy the best job prospects.”

And even the training programs for mechanical science careers are more fun than the programs required for a lot of other jobs. Sure, you’ll still have to study and memorize – these are highly specialized jobs, after all – but you’ll also spend a lot of time with your hands on things like engines, steel, circuit boards and propellers. Ready to check out your options? Take a look!

Register With Imagine America To Apply For ScholarshipsExploring Careers in the Field of Mechanical Sciences

Discover just some of your career options in the mechanical sciences field and what they would mean for your education, your salary potential, your job prospects and your day-to-day experience:

Aircraft and Avionics Equipment Mechanics and Technicians

Will I need a degree? Part 147 FAA-approved aviation maintenance technician school

How much money could I make? Aircraft mechanics earned $63,060, on average, in 2018

Will it be hard to find a job as an aircraft mechanic? Maybe. Opportunities are growing more slowly than average (3 percent projected growth) but there is still a projected employment change of 4,700 new jobs.

Will I need to keep up with Will I need to do on-the-job training? No

Because airplanes are complex machines that are subject to intense, detailed federal regulations and maintenance schedules, there will always be a need for specialized aircraft and avionics mechanics and technicians. These mechanics and technicians maintain and repair aircraft, as well as perform regular inspections required by the Federal Aviation Administration (FAA).

Most aviation mechanics and technicians work in full-time rotating 8-hour shifts in hangars or on airfields near major airports. According to the U.S. Bureau of Labor Statistics, “General aviation mechanics and technicians typically have more flexible schedules than those working for airlines.”

As an aircraft mechanic, I might spend my days doing things like:

- Diagnosing mechanical or electrical problems

- Repairing wings, brakes, electrical systems, and other aircraft components

- Replacing defective parts using hand tools or power tools

- Examining replacement aircraft parts for defects

- Reading maintenance manuals to identify repair procedures

- Testing aircraft parts with gauges and other diagnostic equipment

- Inspecting completed work to ensure that it meets performance standards

- Keeping records of maintenance and repair work

Automotive Service Technicians and Mechanics

Will I need a degree? You’ll need a postsecondary non-degree award

How much money could I make? Auto mechanics earned $40,710, on average, in 2018

Will it be hard to find a job as an auto mechanic? Maybe. Open positions are shrinking, (negative one percent projected growth) with a projected employment change of 6,400 fewer jobs.

Will I need to do on-the-job training? Short-term

The Bureau of Labor Statistics says that “automotive service technicians and mechanics, often called mechanics or service techs, inspect, maintain, and repair cars and light trucks. Although service technicians work on traditional mechanical systems, such as engines, transmissions, and drivebelts, they must also be familiar with a growing number of electronic systems. Braking, transmission, and steering systems, for example, are controlled primarily by computers and electronic components.”

Most service technicians work full-time, including some evenings and weekends. They’re often on their feet for long hours, and sometimes have to do their work in uncomfortable positions.

As a certified mechanic, I might spend my days doing things like: :

- Identifying problems, often by using computerized diagnostic equipment

- Planning work procedures, using charts, technical manuals, and experience

- Testing parts and systems to ensure that they work properly

- Following checklists to ensure that all critical parts are examined

- Performing basic care and maintenance, including changing oil, checking fluid levels, and rotating tires

- Repairing and replacing worn parts, such as brake pads, wheel bearings, and sensors

- Performing repairs to manufacturer and customer specifications

- Explaining automotive problems and repairs to clients

Electricians

Will I need a degree? No, just a high school diploma

How much money could I make? Electricians earned $55,190, on average, in 2018

Will it be hard to find a job as an electrician? It shouldn’t be. The occupation is growing faster than average (10 percent projected growth) with a projected employment change of 74,100 jobs.

Will I need to do on-the-job training? You’ll need to do an apprenticeship

Most all homes, businesses and factories run on electrical power, communications, lighting and control systems to control their lighting, temperature, appliances and equipment. Electricians install, maintain and repair these systems to keep people’s lives and jobs easier, more comfortable and safe.

Electricians generally work both indoors and outdoors in a variety of conditions, traveling between homes, businesses, factories, and construction sites to install, maintain and repair power and communications systems.

As an electrician, I might spend my days doing things like: :

- Reading blueprints and technical diagrams

- Installing and maintaining wiring, control, and lighting systems

- Inspecting electrical components such as transformers and circuit breakers

- Identifying electrical problems using a variety of testing devices

- Repairing and replacing wiring, equipment and fixtures using hand tools and power tools

- Following state and local building regulations based on the National Electrical Code

- Directing and training workers to install, maintain, and repair electrical wiring and equipment

Bureau of Labor Statistics, U.S. Department of Labor, Occupational Outlook Handbook, Electricians

Check Out Schools That Offer This Program

Heating, Air Conditioning, Ventilation and Refrigeration Mechanics and Installers

Will I need a degree? You’ll need a postsecondary non-degree award

How much money could I make? HVAC mechanics earned $47,610, on average, in 2018

Will it be hard to find a job as an HVAC mechanic? It shouldn’t be. Opportunity is growing much faster than average (13 percent projected growth) with a projected employment change of 46,300 jobs.

Will I need to do on-the-job training? Yes, there will be long-term on-the-job training

Heating, air conditioning, and refrigeration (HVACR) mechanics and installers work on the systems that control the temperature and air quality in buildings like homes and businesses. Their work is important not only for comfort level, but because climate-controlled environments make it possible to store and transport food, medicine, and other perishable items. Some technicians may undergo additional training (formal or on-the-job) to specialize in specific HVCAR systems or products like commercial refrigeration, solar panels or radiant heating.

HVAC work can be uncomfortable and dangerous. Technicians often work in awkward or cramped spaces, outdoors in inclement weather, or in buildings that are uncomfortable because the air conditioning or heating isn’t working. This profession has one of the highest rates of injury across all occupations, according to the BLS.

As an HVAC mechanic or installer, I might spend my days doing things like:

- Using blueprints and designing specifications to install and repair HVACR systems

- Connecting systems to fuel and water supply lines, air ducts, and other components

- Installing electrical wiring and controls and testing for their proper operation

- Inspecting and maintaining customers’ HVACR systems

- Testing individual components to determine necessary repairs

- Repairing and replacing worn or defective parts

- Determining HVAC systems’ energy use and making recommendations to improve their efficiency

Industrial Machinery Mechanics, Machinery Maintenance Workers and Millwrights

Will I need a degree? No, you’ll need a high school diploma or equivalent

How much money could I make? Industrial machinery mechanics earned $51,6300, on average, in 2018

Will it be hard to find a job as an industrial machinery mechanic? It shouldn’t be. Opportunities are growing as fast as average (5 percent projected growth) with a projected employment change of 27,600 jobs.

Will I need to do on-the-job training? Most millwrights go through a four-year apprentice program

According to the BLS, “Industrial machinery mechanics and machinery maintenance workers maintain and repair factory equipment and other industrial machinery, such as conveying systems, production machinery, and packaging equipment. Millwrights install, dismantle, repair, reassemble, and move machinery in factories, power plants, and construction sites.”

Most of these workers work in factories, refineries, food-processing facilities, power plants and on construction sites. They generally work full time during regular business hours, but may be on call for nights and weekends – often on an overtime basis.

As an industrial machinery mechanics, maintenance worker or millwright, I might spend my days doing things like:

- Reading technical manuals to understand equipment and controls

- Disassembling machinery and equipment when there is a problem

- Repairing or replacing broken or malfunctioning components

- Performing tests and running initial batches to make sure machines are running smoothly

- Adjusting and calibrating equipment and machinery to optimal specifications

- Detecting minor problems by performing basic diagnostic tests

- Cleaning and lubricating equipment or machinery

- Checking the performance of machinery

- Testing malfunctioning machinery to determine whether major repairs are needed

Small Engine Mechanics

Will I need a degree? No, but vocational school training will give you an edge in the job market

How much money could I make? Small engine mechanics earned $37,060, on average, in 2018

Will it be hard to find a job as a small engine mechanic? It shouldn’t be. Opportunities are growing as fast as average (6 percent projected growth) with a projected employment growth of 4,900 jobs.

Will I need to do on-the-job training? Probably

Small engine mechanics diagnose, adjust, repair or overhaul motorcycles, scooters, mopeds, dirt bikes or similar motorized vehicles. Some may specialize in particular makes and models of bikes or modify and design motorcycles for racing and enthusiasts. They usually work in noisy repair shops, but might make onsite repair calls.

As a small engine mechanic, I might spend my days doing things like:

- Replacing defective auto and motorcycle parts using hand tools, arbor presses, flexible power presses, and power tools

- Connecting test panels to engines and measuring generator output and other performance indicators

- Listening to engines, examining vehicle frames and conferring with customers to determine the nature and extent of malfunction or damage

- Dismantling engines and repairing or replacing defective parts including magnetos, carburetors and generators

- Removing cylinder heads and grind valves to scrape off carbon and replace defective valves, pistons, cylinders and rings, using hand and power tools

- Hammering out dents and bends in frames, welding tears and breaks, then reassembling frames and reinstalling engines

Solar Photovoltaic Installers

Will I need a degree? No, just a high school degree or equivalent

How much money could I make? Solar photovoltaic (PV) installers earned $42,680, on average, in 2018

Will it be hard to find a job as a solar PV installer? No. Opportunities are growing much faster than average (63 percent projected growth) with a projected employment growth of 6,100 jobs.

Will I need to do on-the-job training? A moderate amount

Solar photovoltaic installers assemble, install and maintain solar panel systems on roofs and other structures using a variety of hand and power tools. They mostly work outside, but might need to connect panels to electric grids in attics or crawl spaces.

As a solar PV installer, I might spend my days doing things like:

- Planning PV system configurations based on customer needs and site conditions

- Measuring, cutting, and assembling the support structure for solar PV panels

- Installing solar modules, panels, and support structures in accordance with building codes and standards

- Connecting PV panels to the electrical system

- Applying weather sealant to equipment being installed

- Activating and testing PV systems

- Performing routine PV system maintenance

Plumbers, Pipefitters and Steamfitters

Will I need a degree? High school degree or equivalent

How much money could I make? Plumbers, pipefitters and steamfitters earned $53,910, on average, in 2018

Will it be hard to find a job as a plumber, pipefitter or steamfitter? It shouldn’t be. Opportunities are growing much faster than average (14 percent projected growth) with a projected employment change of 68,200 jobs.

Will I need to do on-the-job training? Yes, you would complete a formal apprenticeship

According to the BLS, “the movement of liquids and gases through pipes is critical to modern life. In homes, water is needed for both drinking and sanitation. In factories, chemicals are moved to aid in product manufacturing. In power plants, steam is moved to drive turbines that generate electricity. Plumbers, pipefitters, and steamfitters install and repair these pipe systems.”

Plumbers in particular are often required to work odd hours – since they’re on call to handle emergency situations in homes and businesses, they might have to head out to a job site on nights, weekends or holidays.

As a plumber, I might spend my days doing things like:

- Installing pipes and fixtures

- Studying blueprints and following state and local building codes

- Determining the amount of material and type of equipment needed

- Inspecting and testing installed pipe systems and pipelines

- Troubleshooting systems that aren’t working

- Replacing worn parts

Wind Turbine Service Technicians

Will I need a degree? You’ll likely need a postsecondary non-degree award

How much money could I make? Wind turbine technicians made $54,370, on average, in 2018

Will it be hard to find a job as a ? Growing much faster than average (57 percent projected growth) with a projected employment change of 3,800 jobs.

Will I need to do on-the-job training? Yes, long-term on-the-job training

As green energy initiatives continue to grow, giant mechanical devices have cropped up in landscapes across the country. These devices, called wind turbines, convert wind energy into electricity. Three major components make up the wind turbine – a tower, three blades and a nacelle, which contains the equipment that generates electricity. Wind turbine service technicians, or windtechs, install, maintain and repair all three of these components.

They usually work outside, sometimes in confined spaces, and often very high up.

As a wind turbine service technician, I might spend my days doing things like:

- Inspecting the exterior and physical integrity of towers

- Climbing towers to inspect or repair wind turbine equipment

- Performing routine maintenance on wind turbines

- Testing and troubleshooting electrical, mechanical, and hydraulic components and systems

- Replacing worn or malfunctioning components

- Collecting turbine data for testing or research and analysis

- Servicing underground transmission systems, wind field substations and fiber optic sensing and control systems

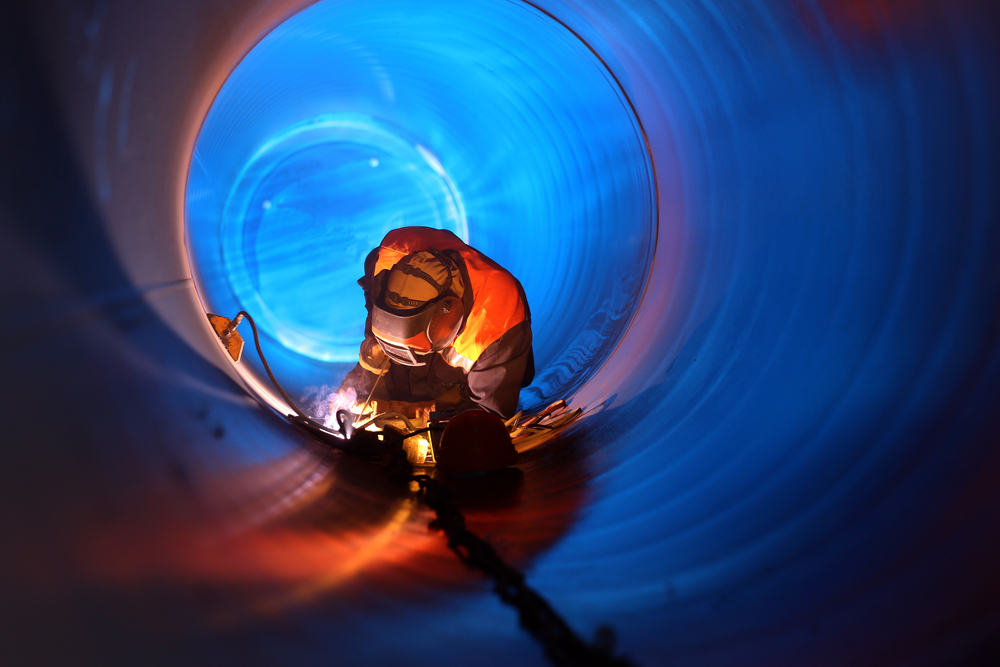

Welders, cutters, solderers and brazers

Will I need a degree? No, just a high school diploma or equivalent

How much money could I make? Welders and related occupations earned $41,380, on average, in 2018

Will it be hard to find a job as a welder? Perhaps. Opportunities are growing more slowly than average (6 percent projected growth) with a projected employment change of 14,500 jobs.

Will I need to do on-the-job training? Yes, moderate on-the-job training

The BLS says “Welders, cutters, solderers, and brazers use hand-held or remotely controlled equipment to join or cut metal parts. Welding is the most common way of permanently joining metal parts. In this process, heat is applied to metal pieces, melting and fusing them to form a permanent bond. Because of its strength, welding is used in shipbuilding, automobile manufacturing and repair, aerospace applications, and thousands of other manufacturing activities.”

They may work outside, often in inclement weather, or indoors, sometimes in a confined areas.

As a welder, I might spend my days doing things like:

- Studying blueprints, sketches, or specifications

- Calculating dimensions to be welded

- Inspecting structures or materials to be welded

- Igniting torches and starting power supplies

- Welding metal parts together

- Monitoring the welding process to avoid overheating

- Maintaining equipment and machinery

Stay tuned for the next edition of Career College Central to take a closer look at the state of Information Technology careers in 2020.

Leave a Reply Cancel reply

- - ADVERTISEMENT - -

Categories

- Alumni Series (13)

- Automotive (57)

- Aviation (15)

- Business (14)

- Business & Arts (18)

- Career College Expositions (8)

- Career Development (96)

- CCC Blog (1)

- CCC Podcast (9)

- College Resource (90)

- College Showcase – Lincoln Tech (6)

- College Showcase – New Jersey (8)

- College Showcase – Pennco Tech (1)

- College Showcase – Universal Technical Institute (2)

- Continuing Education (155)

- Cosmetology (3)

- Counselor Resources (108)

- Criminal Justice (3)

- Dental Assistant (2)

- Education (110)

- Financial Literacy (17)

- Health Sciences (51)

- Heritage Series (3)

- High School Recruitment Series (4)

- Housing Series (10)

- HVAC (8)

- Imagine America Scholarships (12)

- Information Technology (17)

- Massage Therapy (5)

- Mechanical Sciences (109)

- Medical Assistant (12)

- Millennial Student Series (4)

- News (11)

- Nursing (22)

- Online education (13)

- Pandemic Proof Series (4)

- Personal Finance (17)

- Podcast (91)

- Research (11)

- Road Map Series (2)

- Scholarships (12)

- Social Media Series (4)

- Strata Tech (3)

- Student Success (29)

- Study Tips (3)

- Time Managment (1)

- Top 10 (10)

- Trucking (2)

- Uncategorized (14)

- Universal Technical Institute (19)

- Veteran Affairs (8)

- Welding (24)

- Women in Skilled Trades (3)

Tags

- - ADVERTISEMENT - -